CHIMERA reinvents the chicken manure disposal process. Chicken manure requires specific treatment procedures in order to optimize its nutritious and, at the same time, reduce its environmental impact.

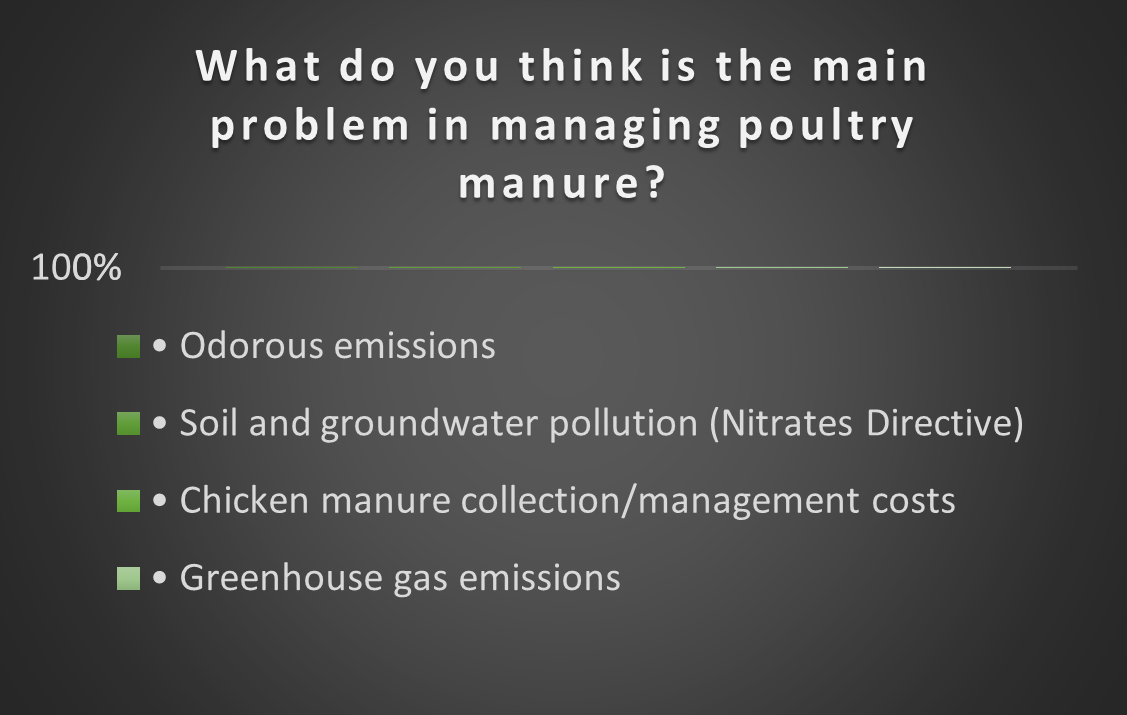

Nowadays, chicken manure disposal is mostly delivered to waste-to-energy plants: farmers have to manage some activities such as shelter and storage, which produce emissions (e.g. ammonia, methane, nitrous oxide, greenhouse gases).

CHIMERA solves all those issues related to the management of chicken manure thanks to a “ready and easy to use” solution, which works in small farms or farm districts for meat (broiler) and/or eggs production laying hen. The dimension of the plant is limited (15 × 9 × 6 m) and can be installed within any sized farm.

CHIMERA’s ambition consists of transforming chicken manure into a fertilizer, while producing energy, and thus creating a circular economy model. CHIMERA is an innovative solution in the name of sustainability.

The CHIMERA project becomes true thanks to the EU financing of the LIFE programme, GA n. LIFE15 ENV/IT/000631, and the collaboration between 3P Engineering Srl, an Italian engineering company and project coordinator of the project, and Renders&Renders V.O.F., Dutch poultry farm.